Well sit down with you and dive deep into your application for a complete understanding. In-Depth Product Reviews Descriptions Videos to Help You Find the Correct Part.

Control Panels Activ Air Automation Ltd

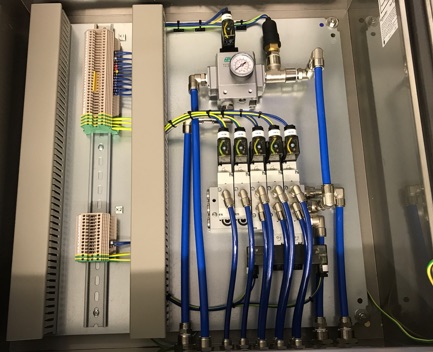

To do that hardware must be purchased and mounted on a back panel and then wired and integrated into the machine.

. Generally Instrument dry air of 50 kgcm2g is source of pneumatic power to all the pneumatically operated Instruments. Tips and Tricks Enclosure ratings filters input and output networking and safety are among enclosure design considerations. When it comes to building your electric and pneumatic control panels you need a company you can trust to bring your design to life.

Control Panel Design. Our team of project managers and technical staff will work with you to choose the capabilities that best suit your needs. Whether you know exactly what you want or you need some guidance tell us your automation and controls needs and well make.

Our control panels include. A consistent plant air pressure and flow is needed for pneumatic devices to operate consistently and reliably. Do you have a pneumatic control panel in need of upgrading or a new application youd like to discuss.

Control panel design starts with the basics and its not just about selecting a cabinet and back panel to house your electrical control hardware. Well control section This is the brain of the system and design of this section depends on the operating parameters and all control signals for the operation of the actuators. Ad Wide Selection of Products from Omron.

While some control units such as modern PLC-based modules might provide manufacturing processes with more technical sophistication pneumatic panels offer a control system that is simple well-maintained easy to use and above all. The major components required to design the pneumatic controller are double acting cylinder 52 way level operated directional control valve pneumatic tubes and latex rubber. Ad Low Prices Wide selection of Industrial Process Control Products.

The starting point for a good pneumatic design is ensuring proper plant supply air pressure. Chemical injection system CI To inject corrosion inhibitors production team will decide which chemical is to be used. Choosing Pneumatic Controls Using the Flow Chart The three essential selection criteria are applied in turn to the machine under consideration.

Electrical and Pneumatic Design. Our controls engineering group understands that a good solution starts with a good design. Media or energy controlled to achieve a desired controlled variable condition.

Moisture in pneumatic air is a common problem so placing the entry low will insure there are no drips on. Well head control panel iii. As a bespoke pneumatic control panel manufacturer API UK is known for its consistency with design from product to product.

Here are some of the features that can be expected from API UKs pneumatic control panel design. The air line from the air supply system to controllers and other devices. Airlane as part of your design team offer impartial help on the correct design of your new project.

We respect the genius required in control panel engineering alongside the demands on your time. Features of APU UKs Pneumatic Control Panel Design Highly resistant to corrosion and durability due to stainless steel design. However all pneumatic Instruments should be designed to worked at minimum Instrument air pressure as specified in IC design basis.

1 - Distance and Reaction Time This criterion eliminates the total pneumatic configuration for machines which are too large. PNEUMATIC CONTROL FUNDAMENTALS ENGINEERING MANUAL OF AUTOMATIC CONTROL 60 Main line. Instrument air quality should be in accordance with ANSIISA-7001.

Airlanes pneumatic control panel build service designs and assembles to your specification ready for installation. A recommended practice is to put the pneumatic penetrations low in the panel. Usually plastic or copper tubing.

Hydraulic and Pneumatic Control Panel Design and Fabrication Services in Houston Mako Oilfield Services specializes in providing our customers the best in the customized fabrication of subsea hydraulic and pneumatic control panels. The signal transfer distance D D1 D2is easily evaluated. Air preparation of the plant supply at the machine is important as well and is the first basic pneumatic circuit discussed below.

Hydraulic Pneumatic Control Panel Design and Fabrication Services in Houston TTI Oil provides custom fabrication of control panels including systems assisting designed by us and our customers. Allied is the Distributor of Choice for Industrial Automation Control. Simple design Suitable for hazardous environments.

Double acting cylinder works as a pneumatic actuator and has a rod at its end which is fixed to the latex rubber. Electromechanical Pneumatics Valves Pneumatic use is all about the fundamentals Once clean dry air at the proper pressure is connected and safe get control of the pneumatic cylinders actuators and motors with proper valve selection and flow control. Its about creating a design to control a machine or process.

Bespoke Pneumatic Control Panel Design Increases Efficiency

Pneumatic Control Panel Build Airlane Pneumatics Limited

Pneumatic Control Panel Wholesale Trader From Pune

Pneumatic Hydraulic Control Panel Manufacturer Mounted Control Panels Cabinets Cid Associates Inc

Explosion Proof Pneumatic Control Panel Ex Machinery

0 comments

Post a Comment